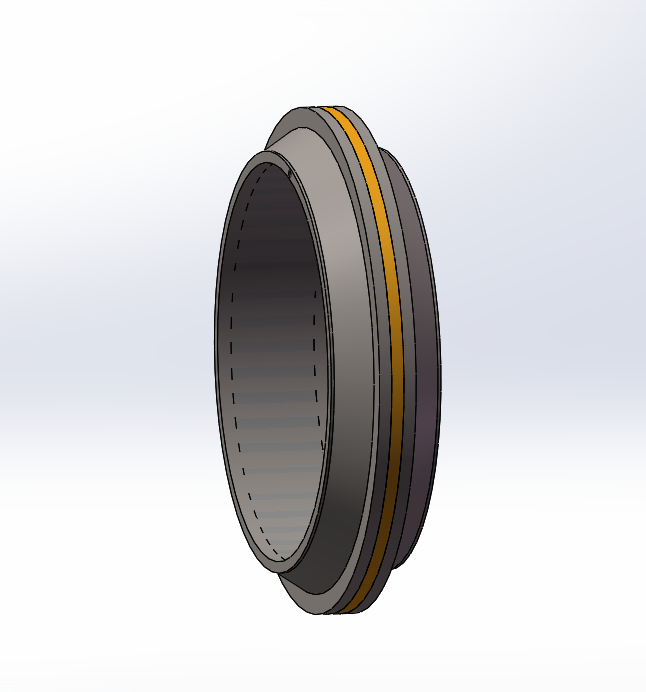

HDPE Puddle Flange Introduction

High-Density Polyethylene (HDPE) puddle flanges are fittings used in various applications, including water management, drainage systems, and industrial piping. They serve as a sealing solution to prevent liquids from penetrating through openings around pipes, providing an effective barrier at the point where the pipe passes through a concrete structure or wall.

Features and Benefits

1. Corrosion Resistance: HDPE material is highly resistant to corrosion, ensuring a long service life for the flange and reducing maintenance costs associated with corrosion-related issues.

2. Chemical Resistance: HDPE is known for its excellent resistance to a wide range of chemicals, making it suitable for use in various industrial applications.

3. Flexibility: HDPE has a high degree of flexibility, which allows the puddle flange to accommodate movement and minor misalignments in the piping system.

4. Lightweight: HDPE puddle flanges are lightweight compared to traditional materials such as steel and iron, making them easier to handle and install.

5. Ease of Installation: HDPE puddle flanges can be easily connected to pipes using various methods, including butt fusion, electrofusion, and mechanical connections, simplifying the installation process.

6. Leak-proof Seal: The tight seal created by the HDPE puddle flange ensures a leak-proof connection, preventing water ingress and maintaining the integrity of the surrounding structure.

Applications

HDPE puddle flanges are commonly used in the following applications:

1. Water and wastewater management systems

2. Drainage systems for buildings and infrastructure projects

3. Piping systems in chemical, petrochemical, and pharmaceutical industries

4. Irrigation systems in agriculture

5. Cooling and heating systems

Installation Guidelines

1. Ensure the pipe and flange surfaces are clean and free from any dirt, debris, or grease before installation.

2. Align the puddle flange with the pipe, ensuring the pipe passes through the center of the flange.

3. Secure the flange to the pipe using the appropriate connection method (butt fusion, electrofusion, or mechanical connections), following the manufacturer's guidelines.

4. Ensure the flange is firmly embedded in the concrete structure or wall, creating a watertight seal around the pipe.

In conclusion, HDPE puddle flanges offer a durable, corrosion-resistant, and lightweight solution for sealing pipe penetrations in various applications. Their ease of installation and leak-proof seal make them a popular choice for water management, drainage systems, and industrial piping.